Rutland Cookie-Cutter Maker Thrives Despite Tariff Pressures

By Compass Vermont, with full attribution to Supply Chain Dive reporting by Antone Gonsalves (Sept. 12, 2025)

Vermont Company Builds Success on Local Supply Chain

Ann Clark, a Rutland-based manufacturer best known for its steel cookie cutters, has largely avoided the financial pain that tariffs have caused other U.S. small businesses. According to a report by Supply Chain Dive (Antone Gonsalves, Sept. 12, 2025), the company’s decision to move production in-house more than two decades ago and rely heavily on U.S.-based suppliers has shielded it from global trade disruptions.

CEO Ben Clark told Supply Chain Dive that the company sources its primary raw material — tin-plated steel — from Maryland-based Titan Steel, which in turn relies on U.S. Steel. Secondary product lines such as icing, food coloring, and baking mixes also use domestic suppliers. The only exception: parchment paper, imported from France.

From Family Start-Up to Market Leader

Ann Clark, founded by John and Ann Clark, now employs about 35 people in Rutland. The company produces between 4 and 5 million cookie cutters annually and generates $10 million to $15 million in revenue, according to Supply Chain Dive. Most sales come from home bakers, though Ann Clark also serves gift shops, boutique kitchenware stores, and national retailers.

The business holds an estimated 65% to 70% of the U.S. market for cookie cutters, Clark said, emphasizing that quality and reliability have helped the Vermont firm compete with cheaper imports.

Sidebar: Ann Clark’s Role in Rutland’s Local Economy

Employment Base: Roughly 35 employees work in the Rutland facility, making Ann Clark one of the steady mid-sized manufacturers in the region.

Economic Contribution: With $10–15 million in annual revenue, the company adds significant weight to Rutland’s manufacturing sector, which has been shrinking in other industries.

Market Reach: While rooted in Vermont, Ann Clark sells nationally through Amazon, its own website, and stores across the country. The visibility gives Rutland a footprint in the broader U.S. baking industry.

Community Anchor: As a family-founded company that has stayed local, Ann Clark represents the kind of homegrown business many Vermont communities rely on for stable jobs and economic resilience.

A Bet on In-House Manufacturing

While the U.S. Chamber of Commerce estimates that tariffs cost small business importers $202 billion annually, Clark told Supply Chain Dive the impact on Ann Clark is so minimal it doesn’t measure it. That protection stems from a choice he made back in 1998 to stop outsourcing and instead build up in-house manufacturing.

“All my friends would say, ‘Why don’t you just buy from China?’ And I said, ‘No, we want to make them ourselves,’” Clark said. “I like making things, so over the years, we figured out how to make cookie cutters quickly and efficiently.”

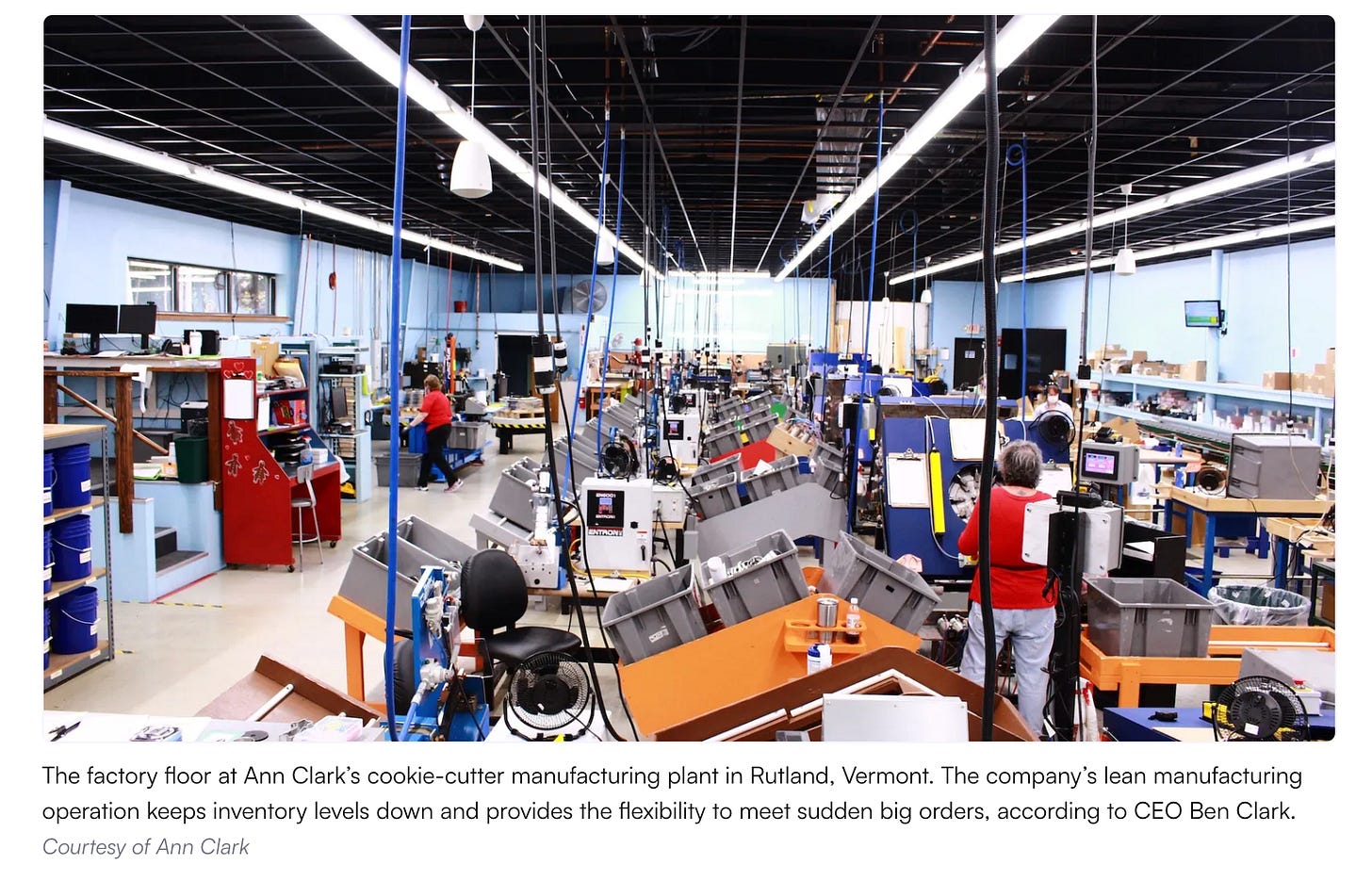

By studying lean manufacturing, Clark said he cut inventory by more than half, producing small lots of each of the company’s 700 shapes while maintaining the flexibility to respond quickly to large or unexpected orders.

Lean, Fast, and Flexible

Ann Clark’s production system is designed to pivot when demand spikes. Clark told Supply Chain Dive that in one instance, the kitchenware retailer Sur La Table forgot to order shamrock cookie cutters for St. Patrick’s Day. Ann Clark filled the emergency order of 2,600 pieces overnight — faster than the retailer’s ordering system could process the paperwork.

That responsiveness, Clark said, is part of what keeps specialty shops and online buyers loyal.

Steel Over Plastic

Unlike some competitors that have shifted to plastic, Ann Clark continues to use steel for its cookie cutters. Clark said the sturdier material provides sharper edges and cleaner cuts, which appeals to bakers seeking detailed shapes.

The approach requires constant innovation and even travel to study other manufacturers’ processes, but Clark argues it pays off in control and independence. “It’s more difficult to make it yourself, but now we have a supply,” he said. “If the sales of a particular product take off, we make it. We’re controlling our destiny.”