BETA Technologies is Gaining Altitude on Its Competitors

A homegrown Vermont company’s pragmatic, step-by-step strategy is setting it apart in the high-stakes race to build the future of air travel.

In the global race to create a new generation of electric aircraft, a Vermont-based company is proving that a quiet, methodical approach might just be the fastest path to success. While competitors grab headlines with massive stock market debuts and futuristic "air taxi" concepts, BETA Technologies, headquartered right here in South Burlington, is building a powerful lead based on a strategy of safety, simplicity, and pragmatism.

The emerging industry, known as Advanced Air Mobility (AAM), promises to revolutionize transportation with clean, quiet, and cost-effective electric flight. But as companies around the world have discovered, the path from a great idea to a certified, revenue-generating aircraft is incredibly difficult. BETA’s unique, two-pronged strategy is not only navigating these challenges but is setting a new standard for operational reality in a field often fueled by hype.

The Two Roads to Electric Aviation

To understand what makes BETA different, you first have to understand the two main types of aircraft competing for this new market:

eCTOL (electric Conventional Take-Off and Landing): Think of these as the next evolution of the airplanes we know today. Aircraft like BETA’s ALIA CX300 are fully electric but use conventional runways for take-off and landing. Their major advantage is a simpler, faster, and lower-risk path to getting certified by regulators like the FAA. They can use existing airports and fit more easily into established safety rules.

eVTOL (electric Vertical Take-Off and Landing): This is the more revolutionary "flying car" concept. Planes like BETA’s ALIA A250, Joby Aviation’s S4, and Archer’s Midnight are designed to take off and land vertically like a helicopter, opening up the possibility of true point-to-point travel without a runway. While transformative, this capability is technically complex and requires regulators to write a whole new rulebook for certifying these "powered-lift" aircraft.

Many companies jumped headfirst into the more complex eVTOL challenge. BETA, however, made a calculated pivot. It is pursuing both paths simultaneously with a single, brilliant airframe design. The ALIA platform, with its distinctive 50-foot wingspan, comes in two versions that share common parts, propulsion, and pilot controls. The CX300 (the conventional plane) is being commercialized first, allowing BETA to enter the market sooner, generate revenue, and gather thousands of hours of invaluable real-world flight data. This data—proving the safety of its batteries, motors, and control systems—then directly supports and de-risks the certification of its more complex A250 (the vertical take-off model).

It’s a classic crawl-walk-run strategy, and it’s giving BETA a tangible lead in operational maturity.

The BETA Ecosystem: Building the Plane and the Gas Station

Perhaps the most significant difference between BETA and its rivals is its commitment to vertical integration. Instead of just designing a plane, BETA is building the entire ecosystem required to support it. At its facilities in Vermont and Montréal, the company designs and manufactures its own proprietary electric motors and battery systems. This gives it complete control over its technology and supply chain.

But its masterstroke is its charging infrastructure. BETA has developed and is deploying a network of its own multimodal chargers. These "Charge Cube" stations are the first in the industry to receive Underwriters Laboratories (UL) safety certification, a critical milestone for commercial use. The chargers can service both electric aircraft and ground-based electric vehicles, creating a separate, potentially lucrative business line.

As of early 2025, BETA already has 46 charging sites online with another 23 in development. This tangible network, stretching across the country, is a powerful competitive moat that no other electric aircraft manufacturer can currently match.

From Theory to Reality: Unmatched Flight Credentials

While some competitors have focused on simulations and controlled tests, BETA has been busy proving its aircraft in the real world. Its ALIA prototypes have flown more piloted miles than any other eVTOL developer, traveling through the airspace of more than half of the United States and into Canada.

Key milestones that separate BETA from the pack include:

Proven Military Reliability: In a three-month deployment with the U.S. Air Force at Duke Field, Florida, the ALIA CX300 demonstrated an exceptional 98% dispatch reliability, proving its robustness in a demanding, mission-critical environment.

Full Transition Flight: In April 2024, the ALIA A250 eVTOL successfully completed a piloted flight where it seamlessly transitioned from vertical hover to wing-borne flight and back to a vertical landing—a crucial test of its design.

Production and Certification: The first ALIA CX300 built on the company's full-rate production line in Burlington completed its maiden flight in November 2024 and was granted a Special Airworthiness Certificate by the FAA, a sign of the agency's confidence.

Historic Passenger Flight: In a landmark demonstration in June 2025, a BETA aircraft flew a passenger into New York’s major JFK airport, showcasing its quiet operation in the nation's busiest airspace. The low cabin noise allowed for easy conversation without headsets, a stark contrast to conventional aircraft.

This track record has translated into a strong and diverse order book from customers who value reliability over hype. These include:

Cargo: A landmark deal with UPS for 10 firm orders with options for up to 150 more.

Medical: Launch customer United Therapeutics, a pioneer in organ manufacturing, and helicopter ambulance operator Metro Aviation (20 aircraft).

Passenger: Agreements with operators like Blade (up to 20 aircraft), lessor LCI (up to 125), Helijet, and even flag carrier Air New Zealand.

Defense: Foundational contracts with both the U.S. Air Force and U.S. Army.

By focusing first on cargo, medical, and defense, BETA proves its aircraft's safety and economic viability—its estimated energy cost is just $18 per hour versus $347 per hour for a comparable Cessna 208—before making a full-scale push into the passenger market.

The Final Analysis: Who is Really "Winning"?

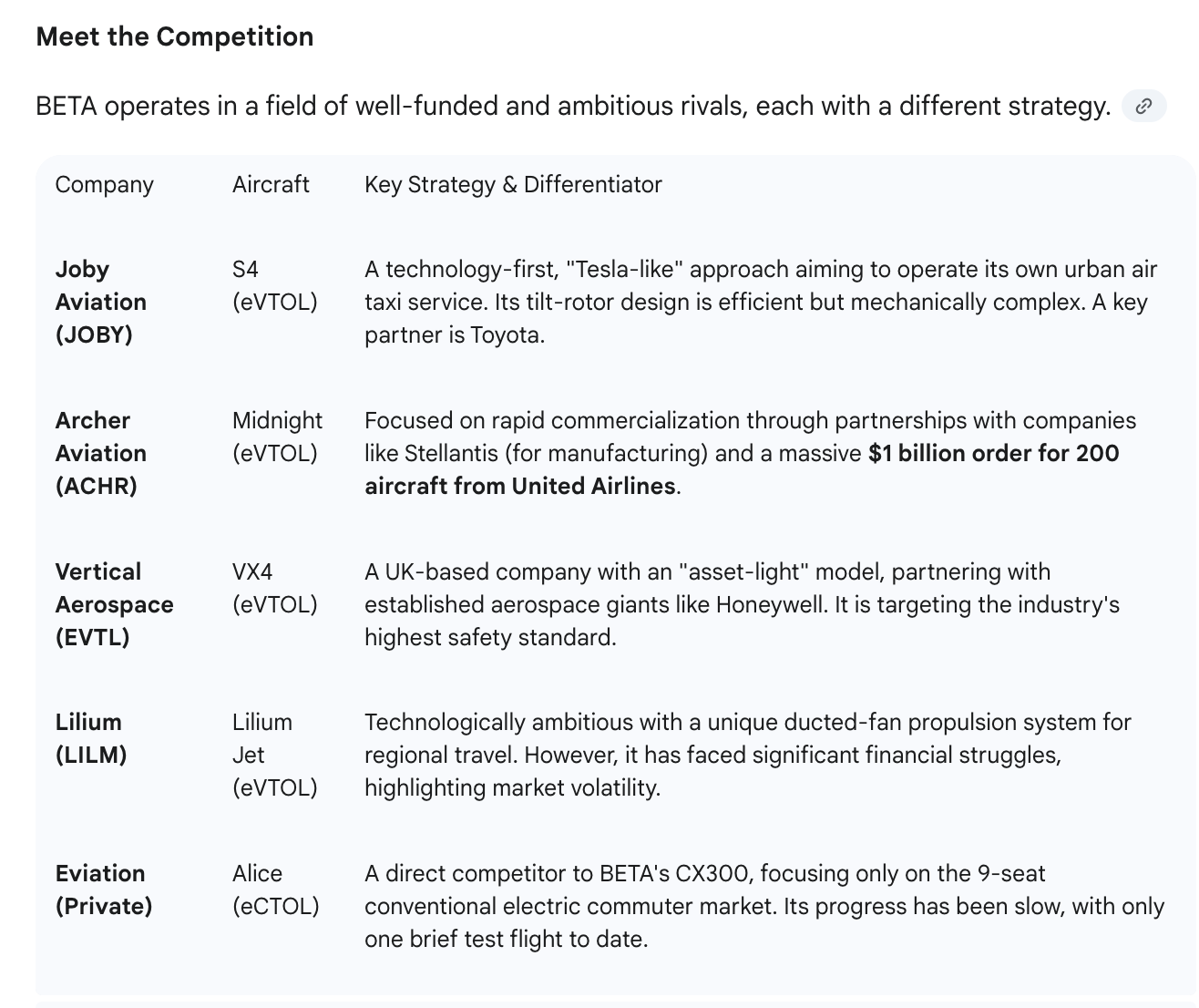

While competitors like Archer and Joby may lead in market capitalization and headline-grabbing airline deals, the question of who is "winning" depends on the metric.

Winning on Hype and Capital: Archer and Joby have leveraged public markets to build formidable war chests and powerful market narratives.

Winning on Operational Reality: BETA Technologies is the unambiguous frontrunner. Its lead is built not on projections, but on tangible achievements: the most miles flown in real-world conditions and proven reliability in the crucible of military operations.

Winning on Strategic Resilience: BETA’s diversified market strategy (cargo, medical, defense, and passenger) combined with its unique charging network gives it the most robust and multi-faceted business model, positioning it to weather market shifts and capitalize on opportunities across the entire AAM spectrum.

By remaining a private company, BETA has been insulated from the short-term pressures of the stock market, allowing it to execute its methodical, long-term plan. This strategic patience is now paying dividends.

For Vermont, BETA's success is a local story with global implications. The path forward will be marked by key milestones, most notably achieving full FAA Type Certification, which is targeted for 2025 for the CX300. As BETA ramps up production at its Burlington facility, it presents a unique opportunity for regional workforce development and for local suppliers to become part of a new, high-tech manufacturing base.

In the high-stakes, high-risk world of aviation, BETA Technologies has shown that the steadiest hand may ultimately win the race. It is gaining altitude on its competitors not by making the most noise, but by proving it can fly the mission.